Engineer Aims To Make Paper Manufacturing More Efficient – News Center

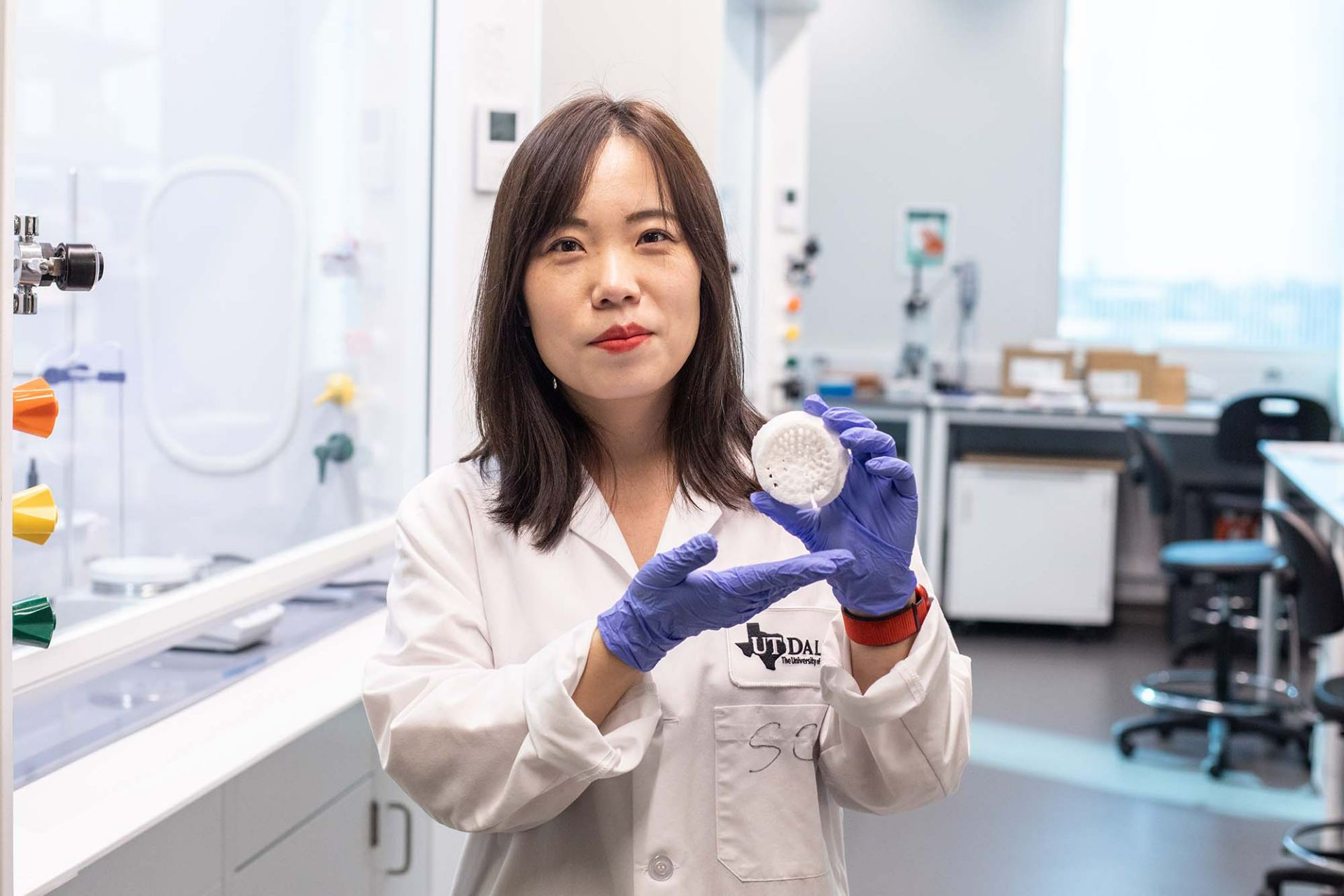

Dr. Shuang (Cynthia) Cui, assistant professor of mechanical engineering at The University of Texas at Dallas, holds the polymer she made to dry paper in manufacturing applying up to 60{e3fa8c93bbc40c5a69d9feca38dfe7b99f2900dad9038a568cd0f4101441c3f9} considerably less vitality than the conventional system. The polymer can repeatedly take up and release water relying on the temperature.

A College of Texas at Dallas researcher is acquiring a new technique to dry paper in producing that employs up to 60{e3fa8c93bbc40c5a69d9feca38dfe7b99f2900dad9038a568cd0f4101441c3f9} fewer electrical power than the conventional approach, in which a pulp and water mixture is flattened and then heated to evaporate the liquid. Dr. Shuang (Cynthia) Cui, supported by a U.S. Section of Strength (DOE) grant, is perfecting a drying method that absorbs and then releases the drinking water as a liquid.

Cui, assistant professor of mechanical engineering in the Erik Jonsson University of Engineering and Laptop or computer Science, been given the $2.3 million, a few-calendar year grant to build the technologies, which is centered on thermo-responsive hydrogels — polymers that repeatedly soak up and launch drinking water relying on the temperature. The grant is aspect of a $57.9 million investment decision by the DOE in exploration nationwide to enable decarbonize the U.S. industrial sector, advance clean-electrical power producing and enhance the nation’s financial competitiveness.

“Developing the polymer entails investigation of chemical compositions and structures in a precise method. We have a recipe to fabricate the polymer, related to cooking,” Cui reported. “We combine the substances alongside one another at tightly managed circumstances like temperature and stirring pace.”

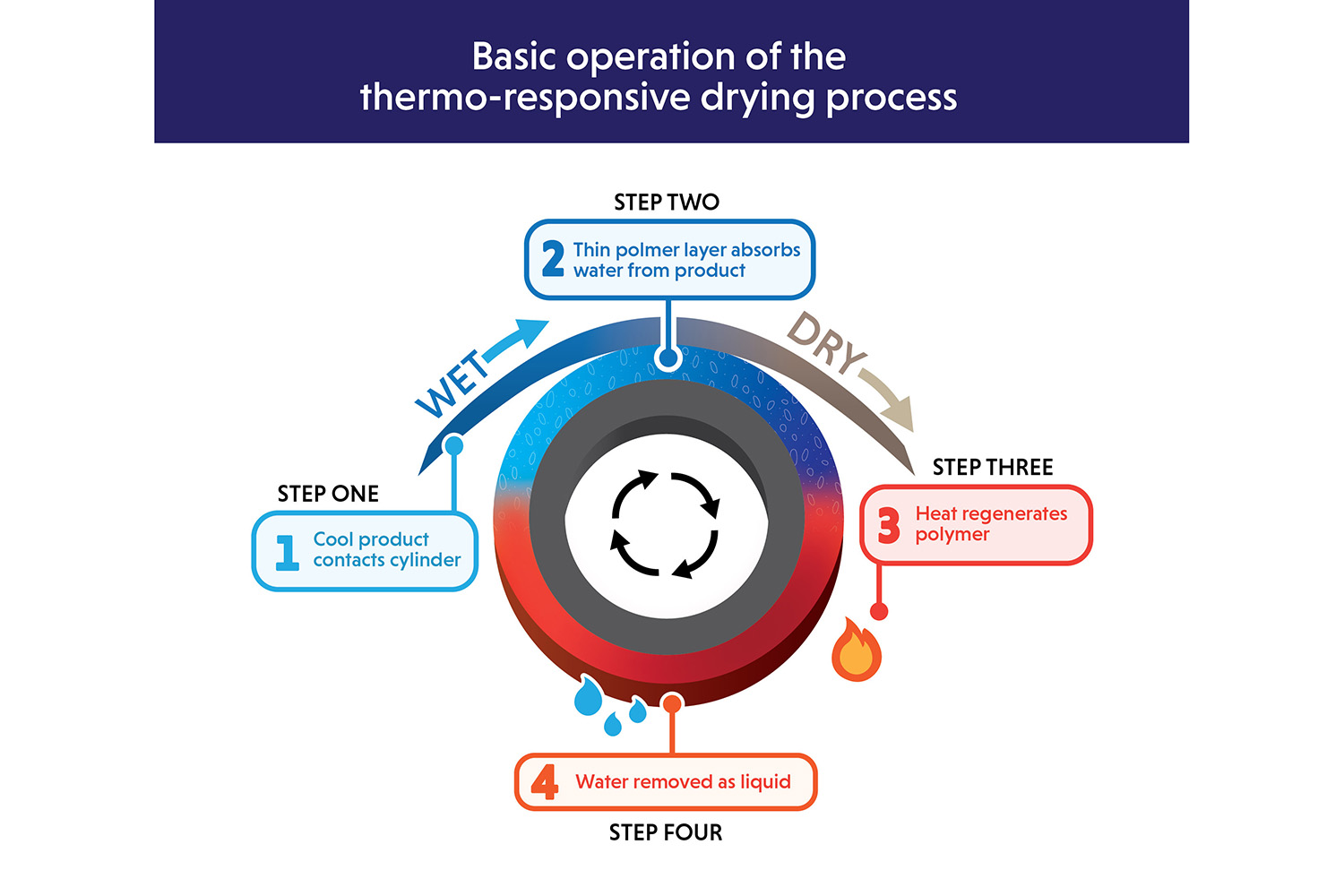

Cui’s exploration is aimed at customizing the polymer to coat cylinders made use of in the manufacture of sheets of paper. When a moist sheet of paper rolls in excess of the top of the cylinder, the polymer coating absorbs the drinking water. As the cylinder rotates, the polymer coating, wet from soaking up the water, dries as it moves as a result of heated air by releasing the water in liquid. Then, the dried polymer coating is all set to dry further sheets of paper, for a constant cycle.

Since it requires significantly less warmth to take out the water from paper as h2o than it does to take out it by evaporation, considerably less energy will be utilized in a ongoing drying procedure, Cui stated. The technological know-how also could be utilized to other manufacturing processes that get rid of water from resources, such as meals merchandise and textiles.

Collaborators on the DOE job consist of Dr. Hongbing Lu, UT Dallas professor of mechanical engineering and holder of the Louis Beecherl Jr. Chair, and experts at Western Michigan University, Auburn College and the National Renewable Energy Laboratory (NREL). Prior to joining UT Dallas in 2021, Cui was a researcher at the NREL.

Cui began exploration on technological innovation to lessen strength use in producing as a doctoral scholar at the University of California, San Diego. In addition to the technique to dry paper throughout producing, Cui is investigating the use of hydrogels to assistance management setting up temperatures extra effectively. The evaporation of drinking water contained in the hydrogels success in a cooling effect for structures that is related to how sweat cools the body.

“We’re doing the job on the decarbonization of properties and industrial processing by way of novel substance growth and program style,” Cui claimed. “The intention is to reduce strength use and carbon footprints so we can have a far more sustainable setting.”